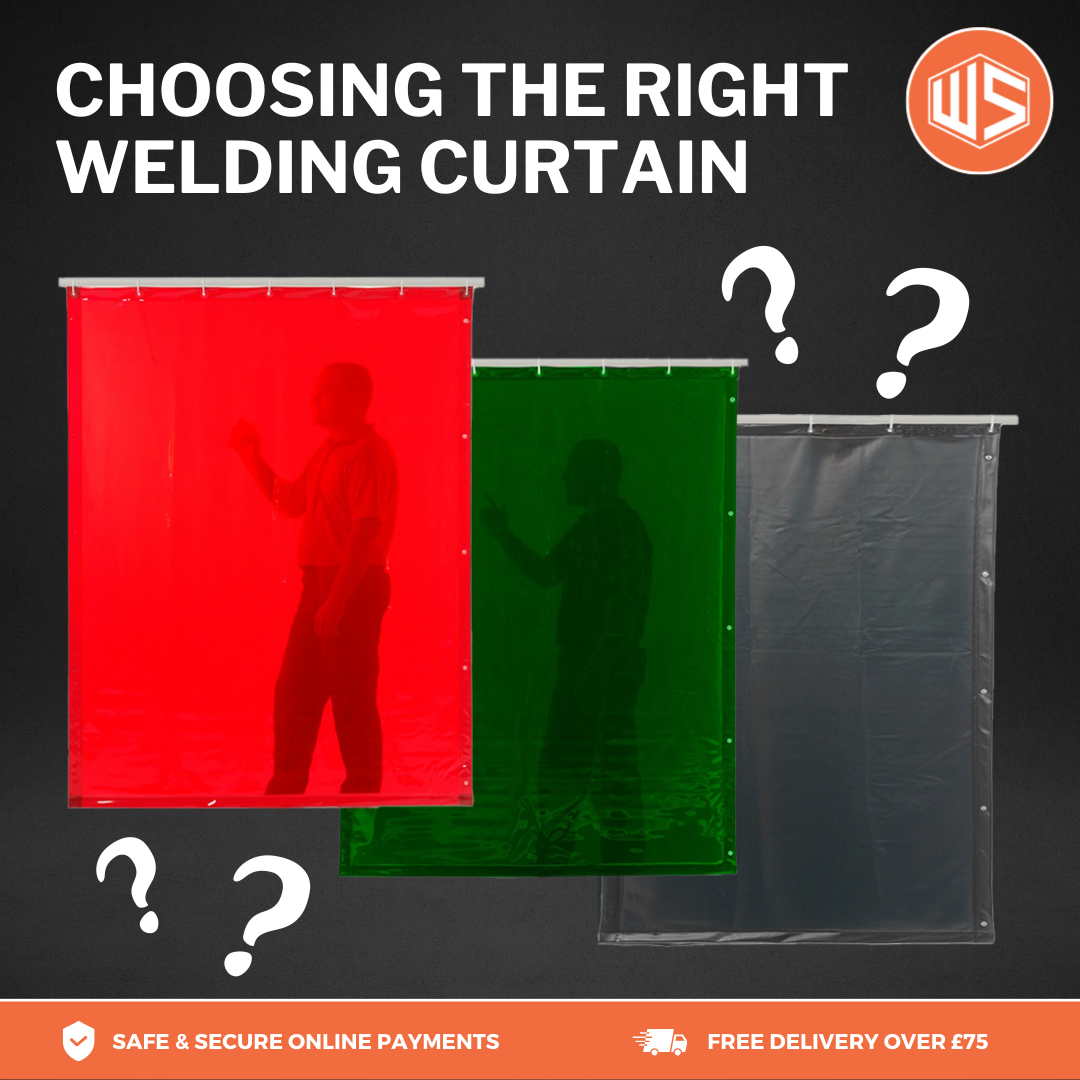

How to Choose the Right Welding Curtain: Orange vs Green vs Dark Green

July 14, 2025When it comes to workshop safety, welding curtains are essential. They protect workers from the harmful effects of welding arc light, reduce glare, and help contain sparks and spatter. But with so many options available, how do you know which curtain is right for your space?

In this guide, we’ll break down the key differences between orange transparent, green transparent, and dark green non-transparent welding curtains - and help you choose the best option for your application.

Orange Transparent Welding Curtains

Best for: Training workshops, multi-operator bays, environments where visibility is essential.

Key features:

- High visibility for safe supervision and oversight

- Blocks harmful UV and blue light

- Allows natural light to pass through

- Complies with EN1598 standards for welding safety

Orange transparent curtains are ideal where monitoring welders is necessary - such as in schools, colleges or busy industrial workshops. They allow others to safely observe from outside the welding bay while still being protected from arc flash.

Green Transparent Welding Curtains

Best for: General welding use, glare reduction, shared workshop spaces.

Key features:

- Reduces visible light more than orange curtains

- Offers better glare reduction

- Still provides moderate visibility

- EN1598 compliant

Green transparent curtains strike a balance between visibility and protection. They’re ideal for shops that need to reduce ambient light while still allowing some visual access to the welding area.

Dark Green Non-Transparent Welding Curtains

Best for: Full arc light containment, private bays, high-risk welding areas.

Key features:

- Blocks all light, including visible, UV, and infrared

- No visibility - total privacy and containment

- Ideal for creating enclosed welding booths or segregated zones

- Helps prevent distraction or arc exposure to nearby workers

When safety and isolation are top priorities, non-transparent curtains are the go-to choice. These curtains are typically used in larger industrial settings, especially where multiple operations are taking place nearby.

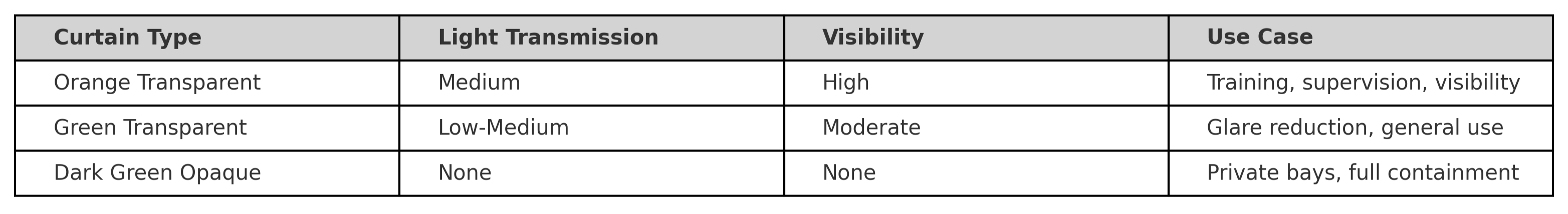

Which Welding Curtain Should You Choose?

Here’s a quick comparison to help:

When selecting a welding curtain, always consider:

- Workshop layout

- Level of supervision required

- Proximity to other workstations

- Compliance with EN1598 safety standards

Find the Right Curtain for Your Workshop

At Welding Superstore, we stock a wide range of EN1598-compliant welding curtains in various colours, transparencies and sizes. We also have portable screens available.

If you’re unsure which curtain best suits your workspace, our experienced team is happy to help. Contact us for expert advice or browse our full range online today.

Explore welding curtains - https://weldingsuperstore.co.uk/consumables-safety/safety-equipment/welding-curtains-frames.html

Enquire here - sales@weldingsuperstore.co.uk

OTHER ARTICLES

What Shade Do I Need for Different Welding Processes? (2025 Guide)

December 8, 2025

Christmas Gift Ideas for Welders: A Helpful Guide for Partners, Friends & Family

December 1, 2025

Mosa Magic Weld 200 YDE Diesel Welder Generator – Compact Power for Serious Mobile Welding

November 24, 2025

The Best Workshop Heaters for Winter - Stay Productive with SIP

November 17, 2025

Three GYS Galaxy 400T W Multi-Process Welders Sold to Customer

November 10, 2025

Save Up to 40% in Welding Superstore’s Autumn Sale!

November 3, 2025

A Best-Seller: Parweld Panther MIG Welding Gauntlets (P3825)

October 27, 2025

Keep Your Workshop Safe and Efficient with Regular Kemper Filter Changes

October 21, 2025

Keep Your Workshop Running Smoothly with Reliable Welding Consumables

October 14, 2025

Portable 400V Power Breakthrough: Instagrid LINK MAX

October 7, 2025