How to TIG Weld Aluminium: A Beginner-to-Intermediate Guide for 2025

December 29, 2025TIG welding aluminium is one of the most challenging yet rewarding processes a welder can master – aluminium behaves very differently to any other metal such as steel. Without the right setup, prep and technique, this material will punish even small mistakes.

In this guide we will take you step-by-step through the entire process from machine settings and torch control to filler rod choice and troubleshooting. This guide is aimed at beginner to intermediate welders so whether you’re completely new to TIG welding aluminium or if you’re just looking to improve your weld quality, this article is for you.

Why Is Aluminium Harder To Weld Than Steel

1. It conducts heat extremely fast

Aluminium pulls heat away from the weld area quicker than steel. This means:

- You need more amperage

- The weld pool forms suddenly

- Thinner material overheats easily

2. The oxide layer melts at a far higher temperature

Aluminium oxide melts at around 2,000°C, while aluminium melts at around 660°C.

This is why:

- Cleaning is essential

- AC balance is needed to “break up” the oxide

- You must avoid dirty or oxidised surfaces

3. It has no colour change to warn you it’s about to melt

Unlike steel, aluminium does not glow as it heats. This makes heat control a major challenge for beginners.

4. It’s incredibly sensitive to contamination

Everything matters:

- Prep

- Clean gloves

- Clean filler rods

- Gas coverage

- Torch angle

Even small contaminants can cause porosity or black soot on the weld.

What You Need To Weld Aluminium

1. An AC/DC TIG welder

AC (alternating current) is required to:

- Remove the oxide layer

- Stabilise the arc

- Provide both cleaning and penetration

An excellent beginner friendly machine would be the Parweld XTT 212DI AC/DC Pulsed TIG Inverter Welder Package. It has advanced pulse TIG and synergic control modes, square wave AC TIG for optimal performance on aluminium and includes a TIG torch, regulagor and other accessories.

2. Pure argon gas (100%)

You can either use industry sized cylinders such as BOC Gases or Pure Argon Disposable Bottles – you would need a different regulator if you chose to use disposable cylinders.

3. The right tungsten

The best choice today is:

- Zirconiated (white)Tungsten for traditional AC use

These electrodes maintain a balled tip shape which is ideal for AC TIG welding, improving arc control and weld consistency.

4. A TIG torch with a gas lens kit

Gas lenses dramatically improve gas coverage, reduce turbulence, and allow longer tungsten stick-out - ideal for aluminium’s sensitivity.

5. Suitable filler rods

The two most common grades:

- 4043 Aluminium TIG Rods - smoother welds, easier for beginners

- 5356 Aluminium TIG Rods - stronger, better for structural work and fabrication

6. Proper PPE

Including:

Step-By-Step Guide To Welding Aluminium:

Step 1 (Preparing the Aluminium)

Prep is one of the biggest factors in weld quality, especially when welding aluminium. If you don’t nail your prep and remove contaminants, you are likely to get welding defects such as porosity (gas pockets which reduce integrity of the weld), slag and cracks.

1. Remove the oxide layer

Use:

- A stainless-steel wire brush dedicated ONLY for aluminium such as Abracs Scratch Brush For Stainless Steel

Or

- scrape with a carbide tool

2. Degrease thoroughly

Use:

- Acetone

- Isopropyl alcohol

Oils, fingerprints and coolant residue all cause porosity.

3. Abrade if needed

For thicker or heavily oxidised material, lightly abrade using:

- Scotch-Brite

- Fine aluminium oxide flap disc

4. Clean the filler rod too

Many welders skip this step and it often causes porosity issues.

Use:

- A Scotch-Brite pad to remove surface oxidation

- Clean rage to wipe with acetone to remove oils and dirt

Make sure you spin the rod as you wipe to ensure it's spotless before use.

Step 2 (Setting Up Your TIG Welder For Aluminium)

Settings vary by machine but these guidelines will get you very close and are a good rule of thumb to go by.

AC Balance

Controls the split between:

- Electrode positive (cleaning)

- Electrode negative (penetration)

A common starting point is 70% Penetration / 30% Cleaning for general use.

You can adjust it to add more cleaning (e.g. 60/40) for dirtier aluminium to remove stubborn oxides. The key is to find the sweet spot where you get enough cleaning for a good weld without sacrificing tungsten integrity or arc stability.

AC Frequency

AC frequency controls the arc’s focus and heat.

A solid starting point for most jobs is around 100-120 Hz as it is a versatile all-around setting.

From this point you can adjust depending on your requirements:

Higher frequencies (e.g. 150–250+ Hz):

- Very focused and arrow the arc

- Improve control

- Reduce the wandering arc effect

Higher frequencies are ideal for thin aluminium, tight joints and stacking beads.

Lower frequencies (e.g. 50-80 Hz:

- Produce wider beads

- Increase heat in the part

Lower frequencies are ideal for thick aluminium or when you need to lay down more metal / repair larger areas

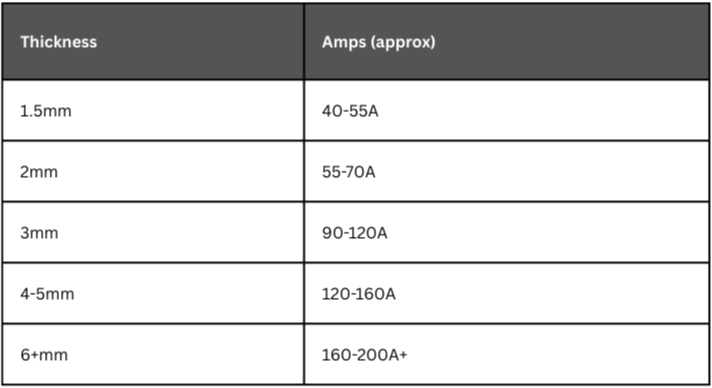

Amperage Settings by Thickness of Material

Below is a general guide on what amperage to set your machines at based on material thickness:

Tip: Get a foot pedal as it gives you the control you need as aluminium suddenly ‘opens up’ into a molten pool.

Gas Flow

Set flow rate around:

- 6–8 LPM with a standard cup

- 8–12 LPM with a gas lens

- Increase slightly in drafty conditions

Tungsten Choice and Prep

- Use 2.4mm for most aluminium work (2-6mm)

- Use 3.2mm for thick aluminium (6mm+)

- Use 1.6mm for thin material (up to 2mm)

Step 3 (Technique: Torch Angle, Body Position & Filler Control)

Torch Angle: Aim for 10–15° push angle

Never pull, always push aluminium TIG.

A pulling torch angle reduces gas coverage and causes:

- Soot

- Porosity

- Oxide contamination

Arc Length: Aim for 1–2mm arc length

This is the distance between the electrode and the workpiece – you want to keep it tight as a long arc:

- Overheats the part

- Causes black soot

- Makes the bead uncontrollable

Filler Rod Control

Establish a molten puddle first, then dip the rod into the leading edge (the front, furthest-advanced part of the molten weld puddle) with a consistent, rhythmic "dab and move" .

If filler melts in your hand:

- Your arc is too long

- You’re feeding too close to the tungsten

- You’re using too thin a rod for the heat input

Travel Speed

Aluminium needs a steady pace:

- Too slow = overheating

- Too fast = cold lap

Consistency matters more than speed.

Step 4 (Common Problems & How to Fix Them)

1. Black Soot on the Weld

Usually caused by:

- Wrong AC balance

- Incorrect torch angle

- Insufficient gas flow

- Dirty aluminium

2. Porosity

Common causes:

- Dirty filler rods

- Contaminated base metal

- Drafts blowing gas away

- Moisture in the material

3. Lack of Penetration

Fixes:

- Increase EN on AC balance

- Increase amperage

- Reduce travel speed

4. Edges Melting Away

Often caused by:

- Too much EN (too much cleaning)

- Too slow travel

- Too much heat concentrated on the edge

5. Tungsten Contamination

Happens when:

- Arc length is too short

- You dip the tungsten

- The filler touches the tip

Final Tips for Clean Aluminium TIG Welds

- Keep everything immaculately clean

- Always use 100% argon

- Use a gas lens where possible

- Don’t rush prep - it’s half the job

- Practice on 2–3mm plate before attempting thin sheet

- Control heat at the end of the weld by tapering off the pedal

Learning to TIG weld aluminium takes time but the payoff is SO worth it. With the right setup and the right habits, your welds will become cleaner, brighter and more consistent.

Need Help Choosing an AC/DC TIG Setup?

Whether you're learning TIG for the first time or upgrading your workshop, our team at Welding Superstore can recommend the right machine, torch, tungsten and consumables for your needs.

Contact us now.

OTHER ARTICLES

MIG, TIG & MMA Welding Courses – 1 Day Classes in Telford

January 19, 2026

What is the difference between MB15, MB25 and MB36 MIG torches?

January 12, 2026

End of Year Reflection 2025: What a Year It’s Been

January 5, 2026

Need Welding Supplies Fast? Click & Collect Available from Our Telford Showroom

December 22, 2025

Welding Superstore Christmas Opening Hours 2025

December 15, 2025

What Shade Do I Need for Different Welding Processes? (2025 Guide)

December 8, 2025

Christmas Gift Ideas for Welders: A Helpful Guide for Partners, Friends & Family

December 1, 2025

Mosa Magic Weld 200 YDE Diesel Welder Generator – Compact Power for Serious Mobile Welding

November 24, 2025

The Best Workshop Heaters for Winter - Stay Productive with SIP

November 17, 2025